BIOPLASTICS

What are bioplastics?

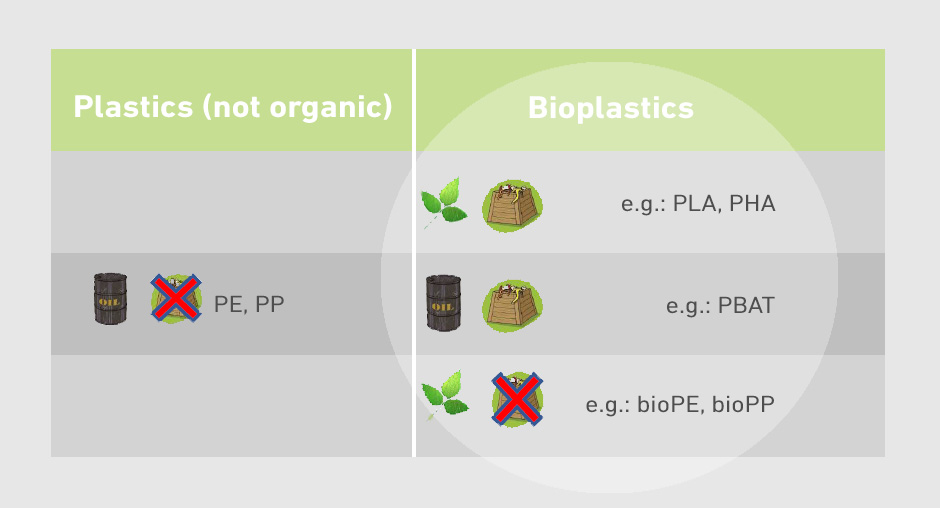

Bioplastics are bio-based and/or biodegradable polymers. Meaning the term bioplastics generally refers to a whole family of materials with different properties and applications that serve as alternatives to conventional fossil-oil based plastics. To date, there is no single definition of the term, but the above description is commonly applied by the main players in the bioplastics industry in Europe.

Bioplastics are usually made from organic raw materials, but after production they are often chemically identical or very similar to conventional plastics. If so, they are suitable for recycling and can be processed together with conventional petroleum-based plastics at the end of the product life cycle. In other cases, new approaches are needed to achieve the quality and technical characteristics required. Today, bioplastics can replace conventional plastics in many areas’ applications. Please note: bio-based plastics are not automatically biodegradable, and biodegradable plastics can also be based on fossil resources.

There are 3 categories of bioplastics:

- Biologically based and biodegradable bioplastics (Info about the products)

- Biologically based and non-biodegradable bioplastics (Info about the products)

- Petroleum-based and biodegradable bioplastics (Info about the products)

What are bio-based plastics?

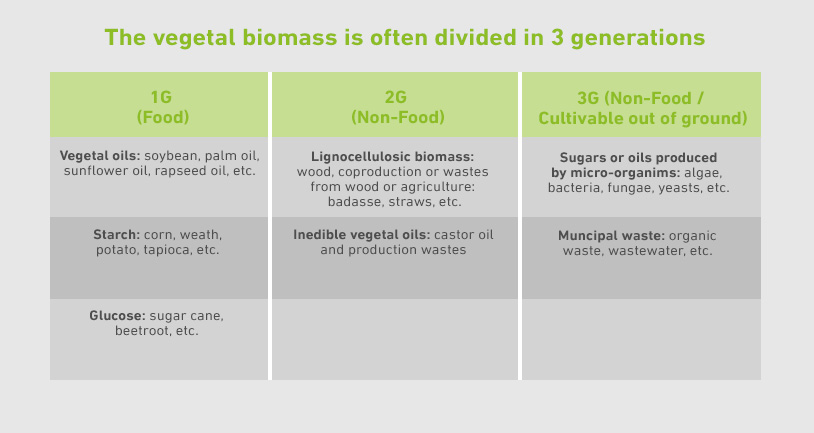

The term bio-based plastics describes raw materials or products made of polymers that are, at least partially, derived from biomass such as plants, naturally occurring renewable structures or through biological pathways such as microbial activity. It is defined by standard EN 16575:2014. In the context of bioplastics, the proportion of biomass can vary widely, as no minimum amount of biological feedstock has been defined as a threshold for the use of the term “bio-based plastic”.

The group of biobased plastics can be classified into three subgroups: 1st generation bioplastics (food-based), 2nd generation bioplastics (non-food-based) and 3rd generation bioplastics (non-food-based and cultivable from soil).

Fully or partially bio-based bioplastics may take on the same chemical structures and properties as some petroleum-based plastics. As a result, such biobased plastics are indistinguishable from a petroleum-based plastic in the recycling stream and can be recycled together. For example, agricultural raw materials such as sugar, maize and cassava can be used to produce bio-based plastics – such as bio-PET, bio-PE and bio-PP – whose molecular structure is similar to their petroleum-based alternatives.

What are biodegradable / compostable bioplastics?

The term bio-degradable plastics describes a family of polymers that may be transformed into natural substances such as water, carbon, and biomass with the help of microorganisms (bacteria, funghi, algae, etc.). The result of biodegradation is CO2, water vapor, and/or methane and possibly by-products (residues, new biomass) that are non-toxic to the environment. Bio-based plastic is not necessarily compostable, and compostable plastic can also be based on fossil raw materials. Currently, there is no overarching standard that regulates or describes the biodegradability of bio-plastics.

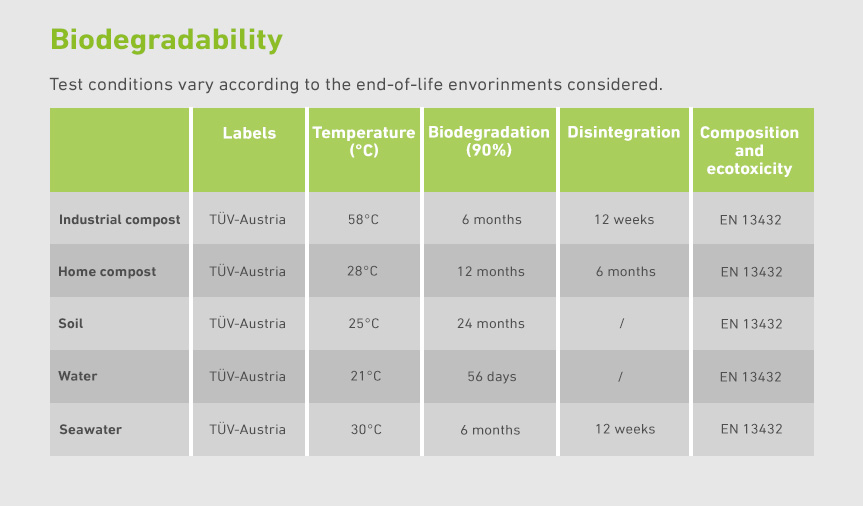

The biodegradability of a polymer is an intrinsic property of the material, depending upon its chemical structure and not on the feedstock it originates from. Hence, the process of biodegradation in the context of bioplastics depends on the material, its application, and the environmental conditions. As a result, there are various forms of biodegradation of bioplastics that differ significantly in the process, and the timeframe in which it takes place and the final outcome. Those are industrial composting, home composting, soil composting, water composting and seawater composting. A plastic bag made of PLA with a thickness of 20 μm, for example, will completely biodegrade in 4 years in a natural environment, compared to 40 days under industrial composting conditions.